Hydraulic power steering systems

Operation of hydraulic power steering systems

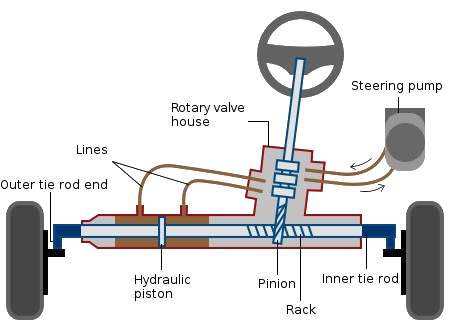

Hydraulic power steering systems use hydraulics to multiply the torque, exerted by the driver on the steering wheel, to a rotating motion of the front wheels. The input of the driver and road condition determine the degree of power steering through a torsion bar that controls the hydraulic pressure on a double acting piston. The hydraulic pressure usually comes from an oil pump driven by the engine of the car. The double acting piston transfers the force via the inner tie rod and outer tie rod end to a rotating movement of the front wheels.

When revising your hydraulic power stering

The main component of a hydraulic power steering system is the rack and pinion which is part of the car's safety system. The most common problems with hydraulic power steering are leakage and play, which is generally due to wear. Possible symptoms include

- Leakage of hydraulic oil is a common problem. Possible causes may be worn boots and contaminated power steering system. In either case, the seals will break and cause the rack and pinion to leak hydraulic oil. Usually this is caused by boots which do not seal properly any more. Hereby, dirt and moisture can build up inside the rack and destroy the seals of the hydraulic piston chamber.

- Sound development may occur in the rack and pinion due to wear on the bearings.

- Problems with steering such as difficulty returning to the middle position, shocking movement during steering, out of the ordinary loose steering and heavier steering.

What can Auto Elect B.V. do for you

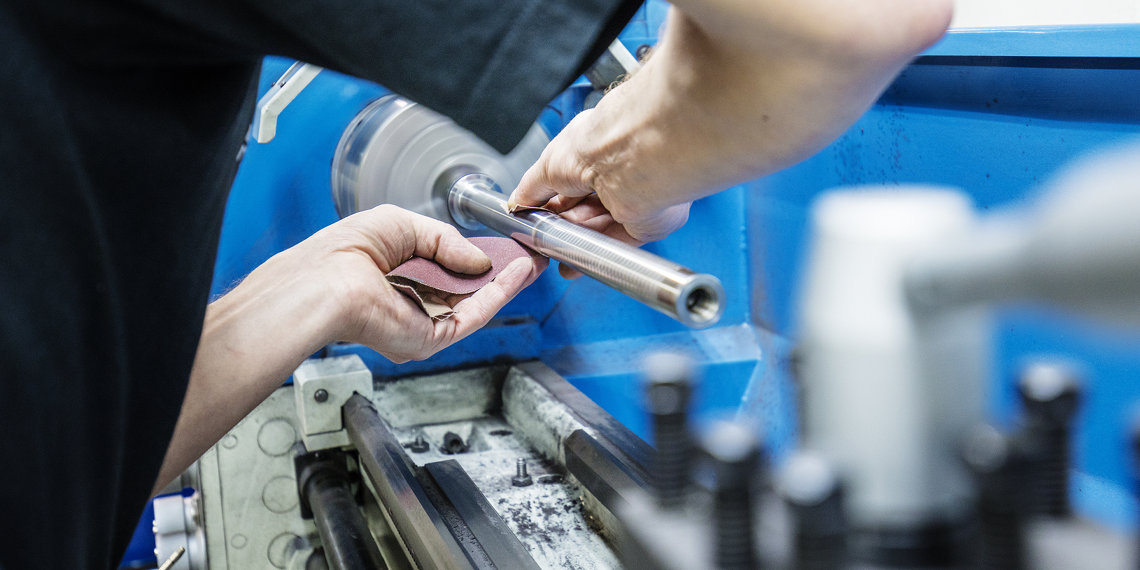

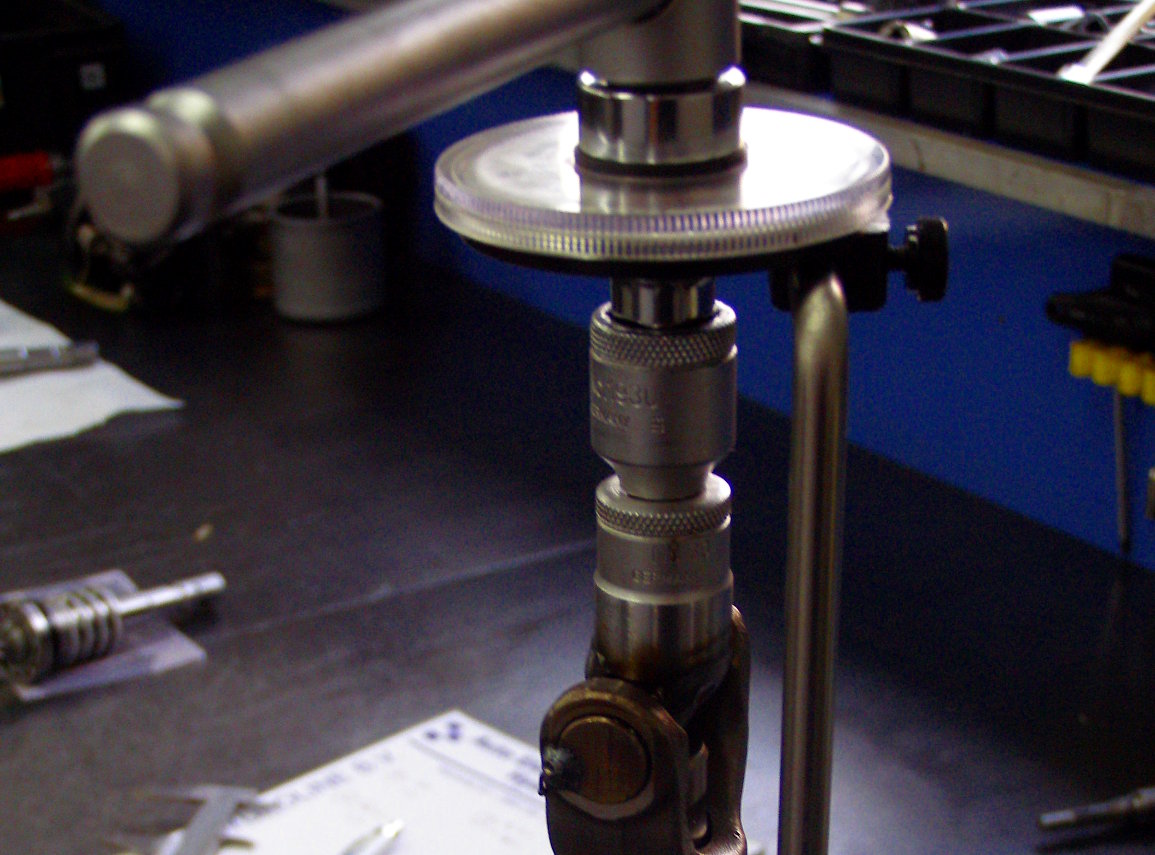

When the rack and pinion does not function properly, revision is often possible. The specialists of Auto Elect B.V. recommend to repair problems with the rack and pinion as soon as possible. Driving with a rack and pinion which does not function properly is dangerous and APK disapprove. Also, problems can worsen, which makes repairs on rack and pinions more expensive. We can revise your rack and pinion and deliver it as new again. The revision is done with extreme care and original components and, if necessary, modifications are made to ensure quality. For rack and pinions of classic cars it sometimes happens that parts are damaged in such way, due to pitting corrosion for example, that copying is necessary. We can also take care of this. All revised rack and pinions are fully tested and calibrated with our self developed test bench. The test bench makes it possible to test rack and pinions under high and low hydraulic pressure. This ensures that the rack and pinion do not leak hydraulic oil and are free from play.

Quality requirements and warranty terms

All revised rack and pinions of Auto Elect B.V. meet high quality standards. The rack and pinions are extensively tested under the toughest conditions and adjusted with self developed test equipment and tools. We provide two year warranty on our products.